Elevate your manufacturing strategy with key resources

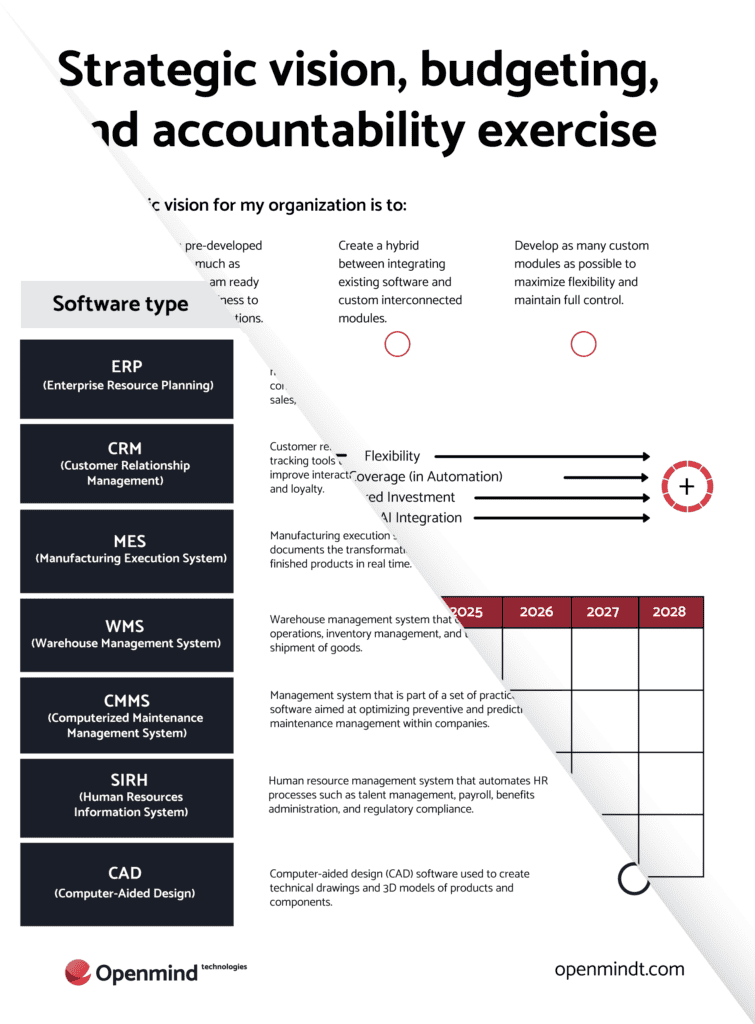

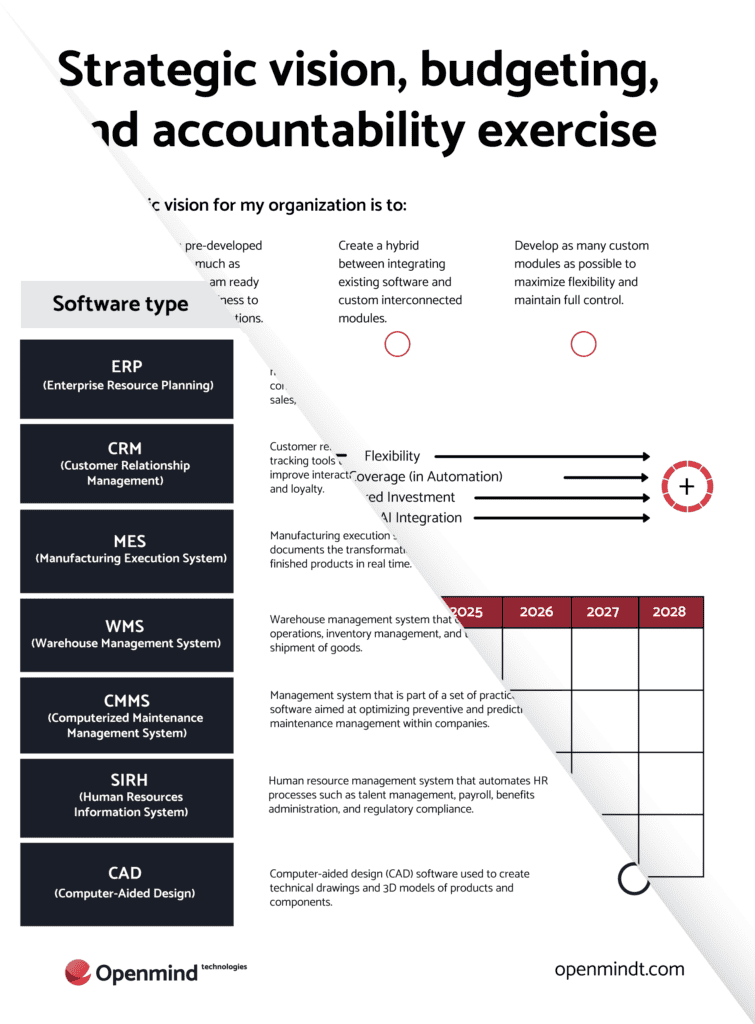

Download our Technological Maturity Self-Assessment & Strategic Vision Exercise tools to assess your software ecosystem profile and to plan for future growth.

Managing a manufacturing company’s production is a daily challenge for operations managers. Overseeing manufacturing, engineering, logistics, and maintenance involves multiple responsibilities to ensure operational profitability. Monitoring key Manufacturing KPIs is essential for effective operations management and informed decision-making. Implementing systems to evaluate and monitor plant performance and human capital optimization is crucial. Specific manufacturing KPIs provide precise, comprehensive data to answer critical strategic questions:

KPIs for the performance of a manufacturing processing chain measure all components involved. These indicators, whether for machine efficiency, resource utilization, or delivery times, provide a clear view of your production rate. Key manufacturing KPIs include:

By closely monitoring these KPIs, you gain valuable insights into optimizing your manufacturing processes and improving overall efficiency.

Having good visibility on your key performance indicators (KPI) allows you to make informed decisions to improve production processes, reduce costs and satisfy customers. In addition, a good understanding of these indicators can help you anticipate market trends and develop strategies to maintain and increase your company’s competitiveness.

Download our Technological Maturity Self-Assessment & Strategic Vision Exercise tools to assess your software ecosystem profile and to plan for future growth.

Because processes have a great influence on operational efficiency, it is advisable to target KPIs that can provide information for this purpose. These KPIs will help you obtain clues about your production cycles, the reliability of your delivery times and also help you prevent possible slowdowns on the assembly line.

Since estimating and respecting delivery time is an issue on which a client bases his or her level of satisfaction, it is advisable to monitor the related data as closely as possible.

Because the production rate of a manufacturing firm is subject to the rate at which it receives the goods it needs to operate, it is important to properly supervise the activities related to it. The use of KPIs for inventory management can avoid several problems such as: stock shortages when procuring raw materials or components, inefficient rotation of finished products, etc.

In collaboration with your maintenance manager, it is necessary to evaluate the level of reliability and performance of the equipment. It is possible, using various KPIs based on specific data on the behavior of your machines, to evaluate, among other things, their capacity of use, downtime according to the reliability of the equipment and the related maintenance costs.

Together with your quality control manager, these measurements are relevant mainly to measure the reliability of your transformation processes based on the output rate of products with no manufacturing defects.

However, depending on the level of digital maturity of a manufacturing company, the use of KPIs in management processes can discourage some people from using them, particularly because of the upstream work that is often necessary to access certain data.

Remember that to ensure the reliability of a KPI, it is important to involve data that is as accurate as possible. A company that refers to data coming from manual or semi-manual processes is at greater risk of involving data corrupted by human error than a company that refers to data generated by proven and automated processes.

With the advent of Industry 4.0, manufacturing companies can leverage real-time data connectivity and analysis to enhance operational monitoring. Implementing KPI display solutions directly on the production floor boosts productivity and supports continuous improvement processes.

Incorporating productivity enhancement into your strategic planning begins with an Industry 4.0 audit to analyze current processes and identify future needs.

Measure your potential for tomorrow today by harnessing the power of Industry 4.0 and manufacturing KPIs.

For more detailed insights into key performance indicators and their application, you can read our article on the 10 Key Performance Indicators to Monitor Using a MES.

Subscribe to receive our exclusive updates directly to your email.

Tell us more about your needs so that we can better route your project to our specific SWAT team.

1

During the brainstorming phase, we work with you to identify potential solutions to your business challenges to generate the technology response that aligns with your business objectives.

2

Through our requirements gathering process, we work closely with you to define and prioritize your needs, ensuring that our solutions are tailored to meet your specific requirements.

3

This phase marks the beginning of our partnership. We’ll finalize the project plan and establish clear communication channels to ensure a smooth and successful project execution.