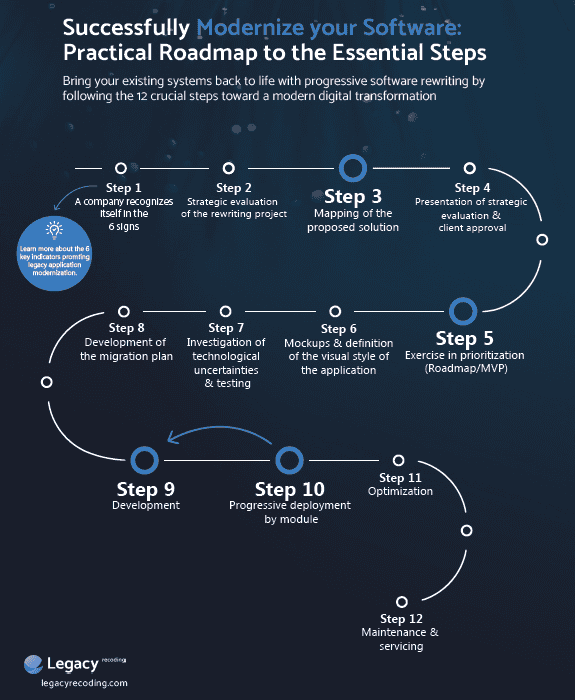

Modernization roadmap guide

Download our free checklist and make sure you don’t miss anything during the modernization stages of your application.

Digital transformation has taken a decisive turn for the steel industry. The recent report from METALCON 2024 speaker Crowe reveals significant trends in the adoption of advanced technologies, with a growing focus on artificial intelligence (AI) and enterprise resource planning (ERP) system modernization.

Given our expertise in digital automation and AI at Openmind Tech, and specifically within the steel sector with Code&Steel, it seemed fitting to bring together a summary of insights from this conference. Below, we highlight key statistics and trends shaping the sector’s future, confirming the importance of embracing these transformative technologies.

Is the steel sector ready for a tech overhaul?

Outdated tech is a barrier for 10% of metal industry companies. While many acknowledge the benefits of modernization, attachment to legacy systems continues to hold some companies back, limiting their agility and potentially affecting their competitiveness in a rapidly modernizing market.

AI adoption has surged from 7% to 24% in the past two years. This growth reflects a keen interest in solutions that go beyond traditional automation. AI models provide valuable insights for operations, inventory management, demand forecasting, and production optimization.

The potential of AI to generate productivity gains is prompting an increasing number of managers to explore these new approaches. For more information and examples of AI integrations for steel companies, check out this article Steel industry & artificial intelligence: how to use AI to be more efficient and generate more profits.

One concerning finding from the report is that 48% of companies lack a clear digital transformation roadmap. Nearly half of the sector is advancing without a strategic plan, leaving them vulnerable to rapid market shifts.

In a competitive industry driven by efficiency and innovation, the absence of a roadmap could jeopardize their position.

Download our free checklist and make sure you don’t miss anything during the modernization stages of your application.

ERPs are essential to steel industry efficiency, yet 50% of companies haven’t updated their ERP systems in at least five years, with some systems remaining unchanged for a decade or more. This highlights a significant gap between the need for modernization and actual investments. An outdated ERP restricts automation capabilities and makes integrating modern solutions like AI or Business Intelligence (BI) tools challenging.

Despite the rise of modern BI solutions, 54% of respondents still rely on Excel for data analysis, with only 6% using their ERP. This indicates a persistent reliance on outdated tools that aren’t optimized for advanced analytics.

Such inertia can severely limit the ability to make rapid, informed decisions in a competitive landscape.

Find out how one metal products manufacturer optimized production planning and boosted operational efficiency with a tailor-made solution.

When asked about future technologies, 41% of respondents prioritize AI. However, 28% admit to lacking sufficient knowledge about AI to take action, revealing a gap between intent and implementation capability.

The Crowe 2024 report spotlights pivotal trends reshaping the steel industry. Adopting AI and modernizing ERP systems are now essential moves for companies seeking a competitive edge. For industry leaders, 2025 could be a turning point, where those embracing these technologies accelerate toward enhanced productivity and efficiency, while others risk falling behind.

By investing in AI and digital modernization, steel companies are positioning themselves to thrive in an era of accelerated technological change.

Subscribe to receive our exclusive updates directly to your email.

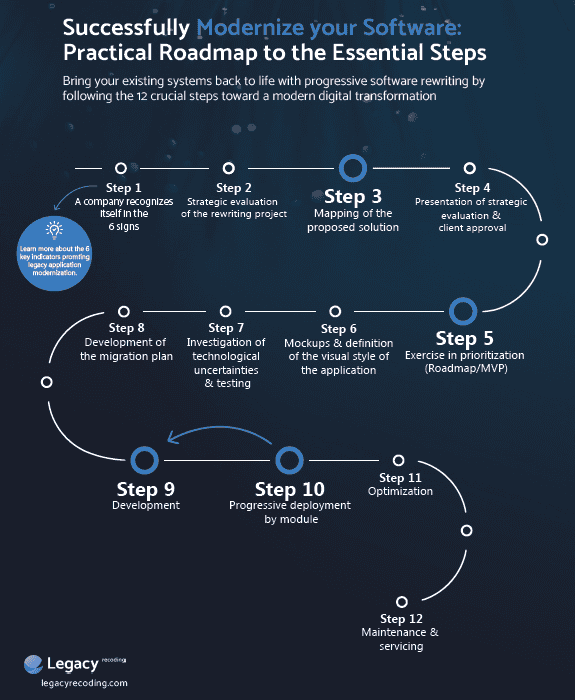

Tell us more about your needs so that we can better route your project to our specific SWAT team.

1

During the brainstorming phase, we work with you to identify potential solutions to your business challenges to generate the technology response that aligns with your business objectives.

2

Through our requirements gathering process, we work closely with you to define and prioritize your needs, ensuring that our solutions are tailored to meet your specific requirements.

3

This phase marks the beginning of our partnership. We’ll finalize the project plan and establish clear communication channels to ensure a smooth and successful project execution.