Elevate your manufacturing strategy with key resources

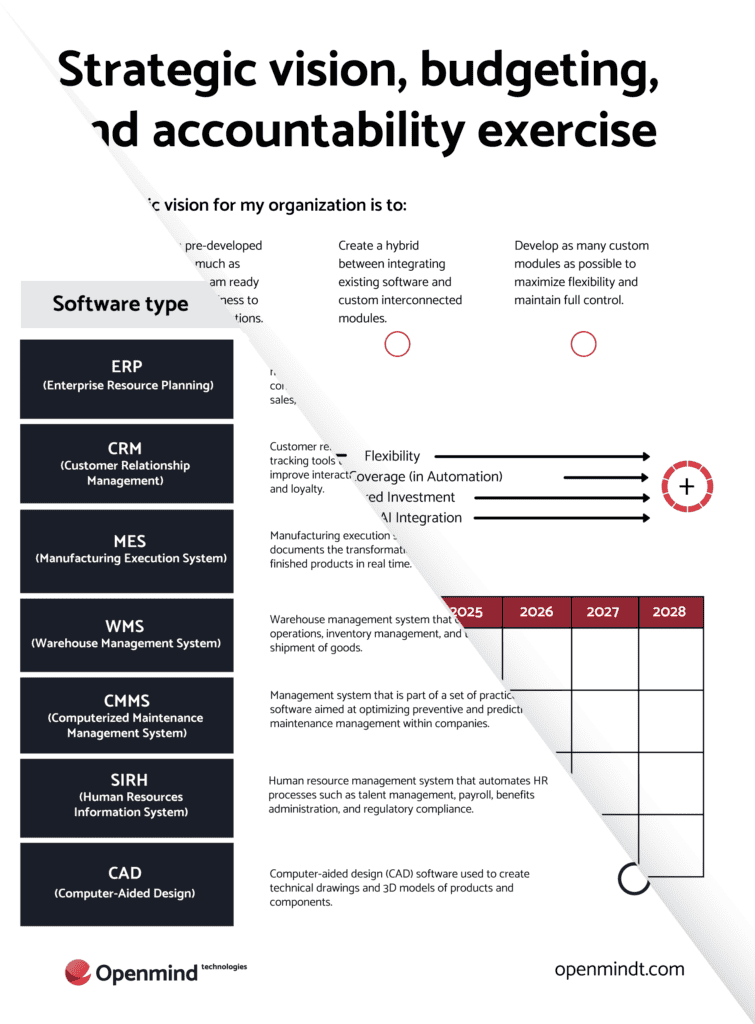

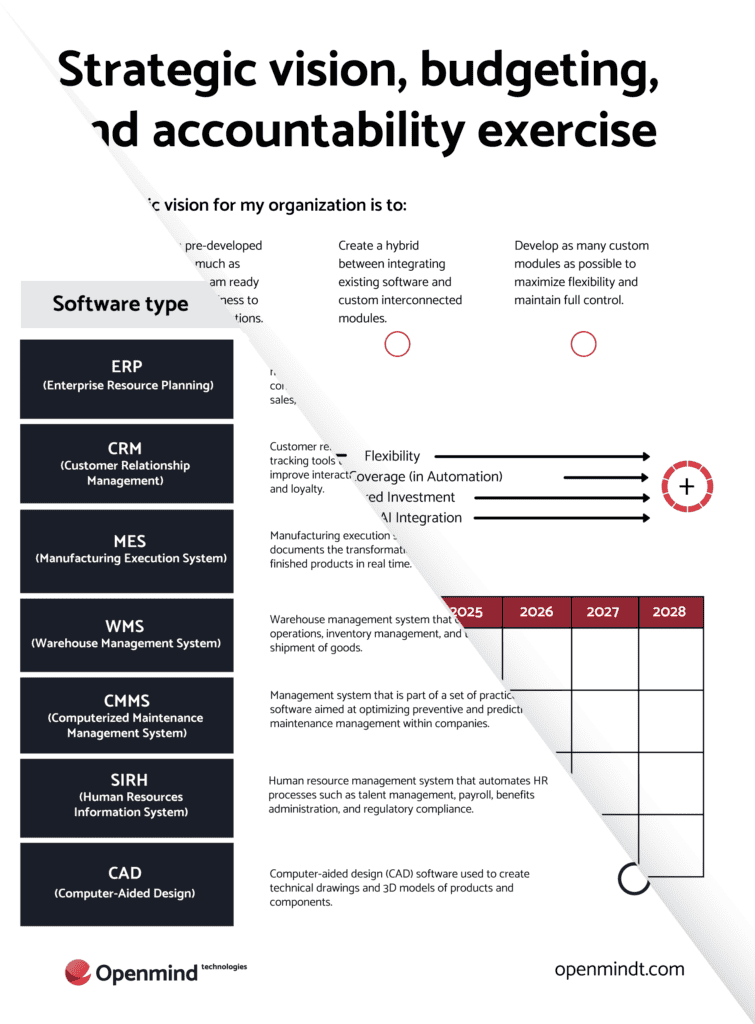

Download our Technological Maturity Self-Assessment & Strategic Vision Exercise tools to assess your software ecosystem profile and to plan for future growth.

In an economic context where manufacturers are facing increasing challenges – complex supply chains, rising customer expectations and increased competitive pressure – a strategic methodology is emerging as a key lever of transformation: Revenue Operations (RevOps).

Yet many companies are still reluctant to adopt this approach, often for lack of information or fear of change.

More than just a strategy, it’s an essential lever for optimizing the performance of manufacturing companies. In this article, we explore the specific challenges of this sector, the fundamental principles of RevOps and the steps you need to take to take full advantage of it.

Manufacturers operate in a complex ecosystem where every mistake is costly. Three major challenges often hold back their growth:

These challenges hinder innovation, growth, and competitiveness. This is where RevOps makes all the difference.

Download our Technological Maturity Self-Assessment & Strategic Vision Exercise tools to assess your software ecosystem profile and to plan for future growth.

RevOps (Revenue Operations) is a methodology aimed at aligning the key revenue-generating departments: sales, marketing, and customer service. By breaking down organizational silos, this approach promotes seamless collaboration and focuses on three key areas:

RevOps transforms how manufacturing companies operate, making them more agile, efficient, and customer-focused.

The first step is to examine existing processes. Where are the friction points? Where do inefficiencies exist? This initial mapping often uncovers unexpected issues, such as duplicates or inconsistencies between departments. Once identified, workflows can be standardized to ensure consistency and smooth operation.

Integrating the right technology tools is the cornerstone of RevOps. This includes:

These tools must be interoperable to eliminate data silos and provide a real-time, unified view across the organization.

The success of a RevOps transformation ultimately depends on the people. It’s crucial to involve employees from the outset, provide them with proper training, and support them throughout the process. Communicating the goals and benefits of the initiative is also key to overcoming resistance to change.

Subscribe to receive our exclusive updates directly to your email.

A manufacturing company that adopts RevOps can expect tangible, measurable results. Key benefits include:

In a sector where competition is fierce, these advantages are a significant strategic asset.

RevOps is not just a trend, it’s an indispensable transformation for the manufacturing industry. By breaking down silos, integrating modern technologies and mobilizing teams, manufacturing companies can reach new heights in terms of efficiency, profitability and customer satisfaction.

For manufacturers ready to take up the challenge, implementing RevOps represents a unique opportunity to modernize their operations and stand out in an increasingly demanding market.

Interested in this content? Listen to our podcast episode (in French) dedicated to the RevOps methodology and its benefits for the manufacturing industry.

Tell us more about your needs so that we can better route your project to our specific SWAT team.

1

During the brainstorming phase, we work with you to identify potential solutions to your business challenges to generate the technology response that aligns with your business objectives.

2

Through our requirements gathering process, we work closely with you to define and prioritize your needs, ensuring that our solutions are tailored to meet your specific requirements.

3

This phase marks the beginning of our partnership. We’ll finalize the project plan and establish clear communication channels to ensure a smooth and successful project execution.